Compressing Hard drives into the Size of a Sugar Cube!

Utilizing the Third Dimension of Data Storage

For the past few decades, electronics has been a cornerstone of modern technology. However, because of recent initiatives of reducing our carbon footprint, advanced materials and architectures followed by cost-effective manufacturing procedures are currently being investigated for the development of cheap low-powered electronic systems.

Think of the 1000Gb hard drive you may have access to. Now multiply that hard drive by 10 and see how big that stack is? Now picture putting ALL that data into a 1 by 1 inch cube. This is on of the major focuses of our groups research.

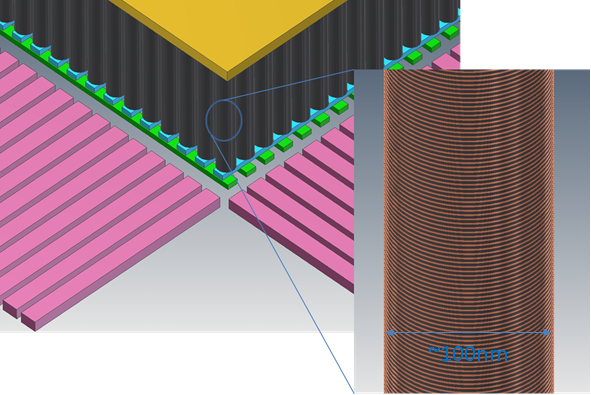

Prof. Russell Cowburn currently is working towards 3-dimensional(3D) magnetic storage technology. The key concept in progressing high density magnetic data storage is to move from storing data horizontally in 2-dimensional plane to discovering methods which allow the creation of 3D memory stacks to store data vertically [1]. My PhD investigates various cost-effective engineering methods, such electrodepostion and anodisation for the development of ordered high-aspect ratio multi-layered nanowire stacks for this application (as visualized in Fig. 1). Both techniques show great promise in reducing fabrication costs as well as compressing information physically within such devices thus shrinking the components themselves.

Fig. 1. A visulatisation of a future 3D array of the stacked magnetic tubes

Even though not energy efficient and cost-effective, industry needs to accommodate billions of users who demand access to information at every moment. Take the internet for example, all this physical knowledge is placed in a storage device, giving you the opportunity to access information anytime anyplace. Moreover, the RAM involved in the process allows you to obtain that memorised data at incredible speeds. Instead of this data being in a form of an external magnetic drive, your connection via the internet allows you to access this information in data warehouses across the globe.

Because of their large factory scale, these warehouses use up a massive amount of energy to allow you constantly access to your information. This is what our research is currently trying to find a solution towards. Data storage devices from RAM to hard drives need to be smaller and operate with minimal energy consumption, and this size reduction will have a dramatic effect on reducing the size of data warehouses and their carbon footprint.

This is what the group is aiming for with their new 3-dimensional magnetic storage technology, which lets us envisage how drastically the size of these data warehouses could decrease. The research group is currently pursuing a promising new data storage method which moves magnetically coupled frustrations between nanometre thick layers of magnetic materials. In these multi-layered magnetic materials, ‘solitons’ which are twists in the magnetisation direction and are stable at room temperature, can be propagated rapidly from layer to layer by an oscillating magnetic field [2]. These are interesting candidates for representing, transporting and storing digital information at unprecendented densities on a chip.

Recently, my research has allowed us to begin correlating various electrodeposition parameters and their effect on the magnetic properties of 10nm thin films of the following electrodeposited magnetic materials Permalloy (Nickel80Iron20), Cobalt-Nickel and Cobalt-Nickel-Iron. The importance of this research is imperative in allowing this low-cost deposition method to mimic that of high-vacuum systems when it comes to tuning the magnetic properties of magnetic thin films such as anisotropy direction. The research also allows the group to create large area high-aspect ratio nanoporous templates for the growth of the arrays of multi-layered nanowires. The procedure allows the group to design nanoporous templates from 40nm to 250nm (Fig. 2) in diameter with heights from 1um to 200um (Fig. 3).

Thin Film Magnetism, Cavendish Laboratory, University of Cambridge

Dishant Mahendru

NanoDTC PhD Student 2010

Thin Film Magnetism, Cavendish Laboratory, University of Cambridge

References:

[1] R. Lavrijsen et al.; “Magnetic ratchet for three-dimensional spintronic memory and logic”; Nature 493; 647-650 (2013).

[2] Patent GB0820844.9, Nov.13 2008; “Magnetic data storage using chiral solitons”