For centuries, scientists have turned to nature to serve as inspiration on how to tackle some of the world’s most challenging scientific problems. Plant cells are particularly interesting and are prime examples of some of nature’s most intricate engineering. Chloroplasts are organelles found in plant cells that not only give leaves their vivid green colour, but are also the site at which light energy is converted to chemical energy. They also happen to be one of the major sites for protein production. Well, what if we could reprogram a chloroplast to produce a specific desirable protein?

The pre-programmed chloroplast would operate similarly to a bioreactor, producing specific proteins that have been encoded into the cell. This would result in very small (and very green!) bioreactors. The major benefit to utilising a chloroplast-based expression platform is that it only requires water and sunlight to synthesise the desired proteins. This is a far cry from the traditional bacteria-based fermentation methods that are currently used to synthesise a wide variety of proteins.

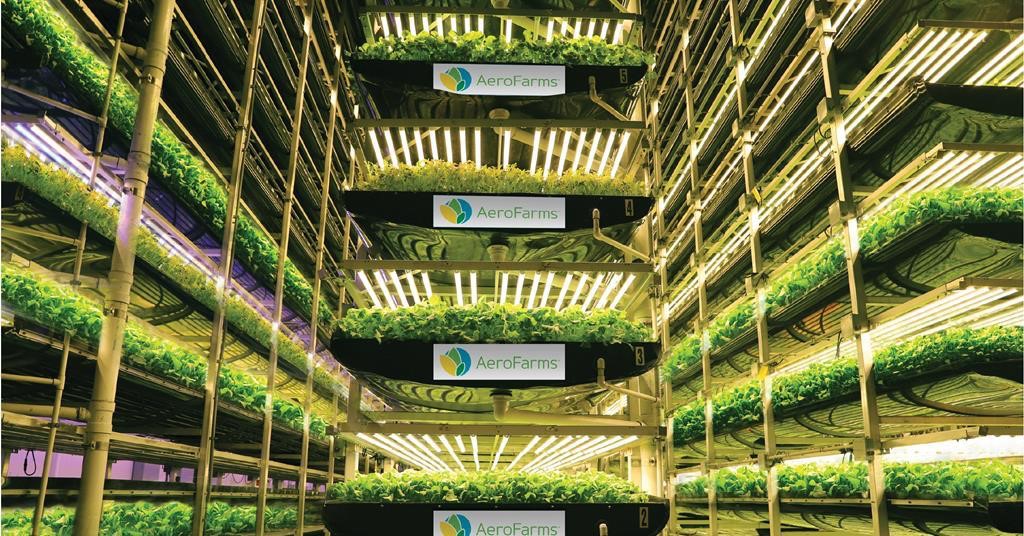

The fermentation-based manufacturing plants are large, highly complex sites that have a high degree of control and automation, as well as extensive energy requirements. Picture something that looks a little bit like the inside of the Tardis, just with the additional pipes, pumps, and reactors. By comparison, pre-programmed chloroplasts could be grown in a vertical farming style system under LEDs to produce the encoded protein. This is not only good news for the environment, where pharmaceutical manufacturing generates 55% more greenhouse gases than the automotive industry, but can also drastically decrease the cost of manufacture. In doing so, we can decrease the economic barrier that currently exists both with respect to access to pharmaceuticals/diagnostics, and the capital investment required to establish a plant in the developing world. On a slightly larger scale, whole tobacco plants are currently being used as hosts for vaccine production in vertical farming style systems, and have even been shown to be capable of synthesising a COVID-19 vaccine!

In my research, I’ll be working in the interdisciplinary space between synthetic microbiology and engineering. I’m hoping to use chloroplasts as a protein synthesis platform to produce genetically encoded photonic nanobodies, which can be integrated into paper-based diagnostic devices. This would result in affordable, accessible, and efficient diagnostic tools.

Image ref: “AeroFarms global farms • growing in vertical farms for elevated flavor.” https://www.aerofarms.com/farms/ (accessed Aug. 06, 2021).

NanoDTC PhD Student, c2020