Control over the 3-D structure of 2-D materials such as graphene helps us to engineer super-materials with properties not usually found in nature.

Two dimensional materials such as graphene have measured as the strongest, stiffest and most conductive materials ever recorded. The ability to control the shape of these materials is essential when tailoring them towards certain applications. Carbon nanotubes can be spun into fibers, making Kevlar-like materials, or pressed into sheets making electrically-conductive papers for use in flexible electronics. Similarly, graphene can be incorporated into plastics to increase strength or blended into conductive inks. However, these applications pale in comparison to what could be achieved by arranging these two dimensional building blocks into three dimensions.

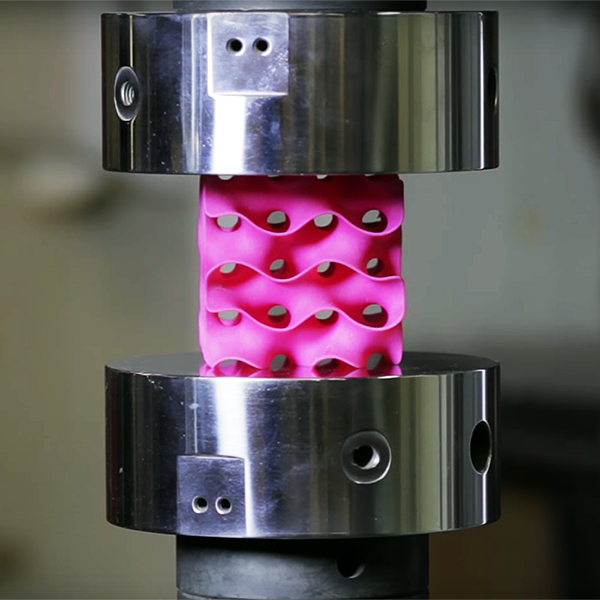

Properties of many ordinary materials change substantially when their density is reduced. For example, foams will be significantly weaker although often more flexible than solid materials due to their 3D volumes becoming increasingly empty. However, some 3D printed lattices have been reported to maintain unnaturally high physical strengths despite drastic reductions in density. Such is the case of graphene which was designed to mimic the hierarchical structure of natural cork resulting in graphene-based foams. Despite lower densities, such materials retained a high energy absorption capability and good electrical conductivity.

My research is focused on finding strategies to structure graphene through the use of tailored templates and composites. These hybrid structures can take any form by mimicking the pre-designed template they are grown on. With careful design of template and use of various graphene composites, we hope to nanoengineer materials stronger than steel but lighter than feathers.

Photo © MIT

Kenichi Nakanashi

NanoDTC PhD Cohort 2014