Electronics has become smaller, smarter and faster. Today, we can pack a computing power matching the performance of a machine which would have weighed hundreds of kilograms 40 years ago, into our pocket. However, state of the art electronics are mainly built on rigid platforms such as silicon and are ill-suited for wearable technology or implants. Biology is soft and elastic, and the materials used within biological systems need to be biocompatible and flexible.

Multidisciplinary research is paving the way for electronic devices that are not only flexible but also conformable and deformable; while maintaining excellent electrical properties under strain. Such ‘stretchable electronics’ based on various polymeric materials is redesigning human-machine interface by ticking all the boxes that makes it suitable for human body integration. Already demonstrated device include soft implants for in-vivo monitoring, electronic skin for prosthetics, portable solar cells for soldiers and wearable touchpad controllers for gaming. However, challenges has impaired their market dominance and those include mechanical and electrical compliances as well as manufacturing issues.

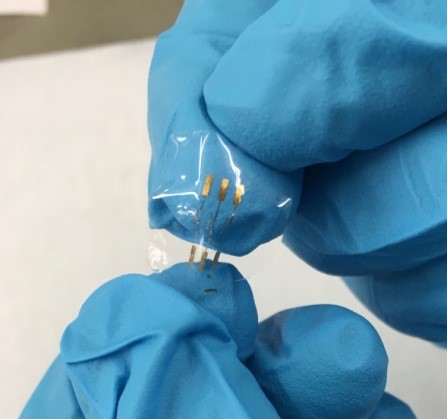

Our research is focused on adapting materials chemistry to design elements for stretchable electronics and ease the manufacturing process by removing the need for specialised equipment and complex protocols. We have already prepared range of electrodes on various flexible and stretchable polymers, and found out that metallic patterns show unusual optical and electrical properties in the nanometer range. Now we would like to use the nano-scale phenomena to design miniaturised bio-sensors and explore other possibilities for interfacing nano-electronics and polymers.

Edward Tan

NanoDTC PhD Associate 2016