Magnetism is all around us. Medical imaging inside the body, creating clean electricity with turbines, storing data on computers – all of these things use magnetism at their core to function. However, it can be difficult to improve these processes, and a large reason for that difficulty is the fact that magnetism is ‘invisible’, but what if there was a way to see magnetism…?

Whilst bouncing iron filings off a trampoline is a great way to visualise big magnetic fields, we are often interested in magnets that are much smaller. In fact, with the nano-magnets that materials scientists are interested in, you could line up 1000 of them across the width of a single human hair. They are so small that waves of visible light are actually bigger than the magnets! This means a normal light microscope can’t see them, and so instead electron microscopes are used because electrons are even smaller than visible light.

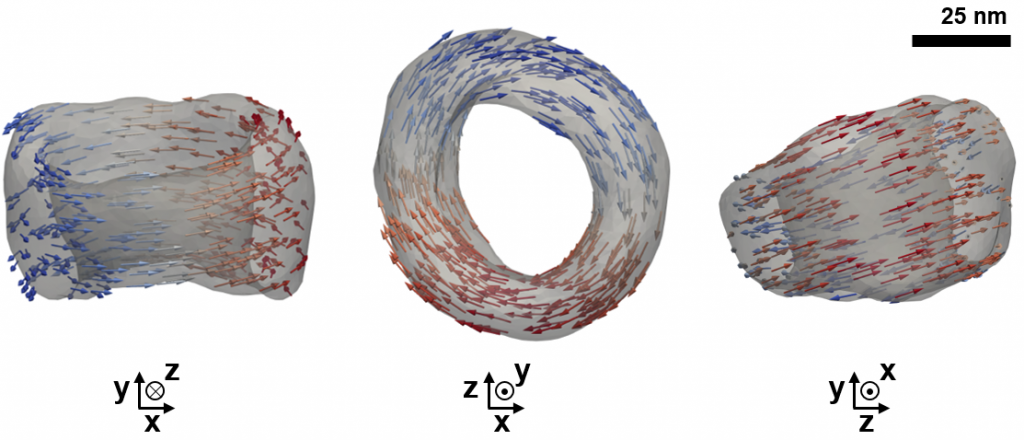

Using electrons to image nano-magnets has another useful consequence; electrons have their own small magnetic fields and can actually be attracted/deflected by nano-magnets (just the same as two fridge magnets can attract/repel each other). By analysing how exactly the electrons are deflected as they interact with nano-magnets, it is possible to actually ‘see’ the magnetism at this small scale. By taking many electron images at different angles, scientists can even build this into a 3D map of magnetism.

One particular type of nano-magnet that my research group has been interested in are doughnut-shaped nanorings made out of iron oxide (commonly known as rust)! The special shape of these magnets means that scientists can actually switch the magnetism on or off. This unique property means that they could potentially be very useful as an anti-cancer treatment: the rings can travel through your body ‘switched off’ until they reach the cancerous tissue where they are then rapidly switched on and off – this causes the rings to heat up and selectively destroy the tumour.

NanoDTC Student, c2018

Supervisors:

Paul Midgley – Department of Materials Science and Metallurgy,

Emilie Ringe – Department of Materials Science and Metallurgy and Department of Earth Sciences,

Richard Harrison – Department of Earth Sciences